How Variable Area Flow Meters Work

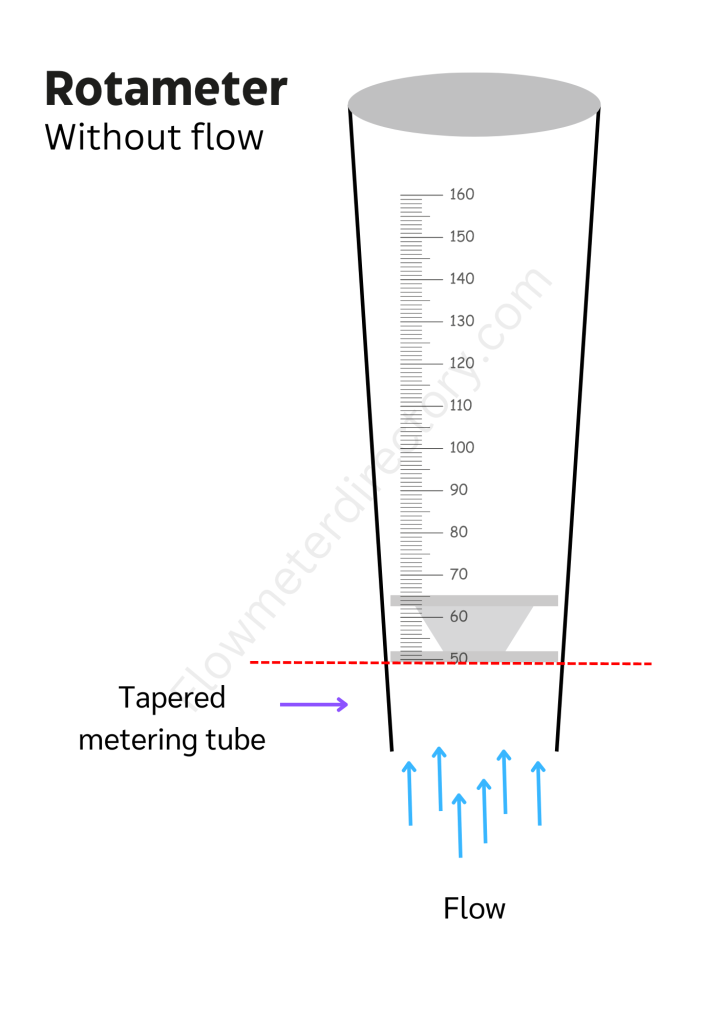

A rotameter is a common type of industrial flowmeter that is used to measure the flowrate of a liquid or gas. It consists of a tapered tube with a float inside. Rotameters work in a simplistic way: fluid raises the float when it passes through the tapered tube. Probably the simplest way to visualize how a rotameter works is to turn to phenomena we see in everyday life. We could use a water fountain with a flow going upwards and placing a tennis ball on the waterspout tells us how fast the water is flowing by how high the tennis ball will rise. Of course, we are going to have a problem balancing the ball but if we were to place a tube over the waterspout, the balancing issue is solved.

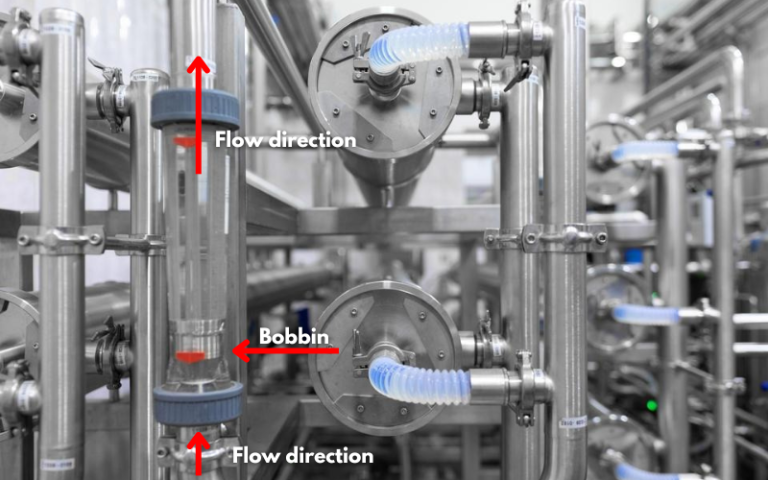

Once someone understands the basic principles of this particular flowmeter type, it is easier to spot in a factory setting. The above image uses something called a Bobbin (which is actually a weighted piece) which moves up and down according to flow rate.

A typically common designed of rotameter is consist of a tapered metering tube with flow going down to up and through the device. The bobbin is the resistance piece which moves higher according to higher flow. The graduations or markings on the device correspond to the flow rate. Rotameters are often use as a visual means of recognizing flow rate although some variations of them are designed with mechanical/electrical outputs. In addition, a flow controller such as a needle valve can be manufactured integrally with rotameter to control flow manually by hand. In this case the rotameter has now become a flow controller or regulator.

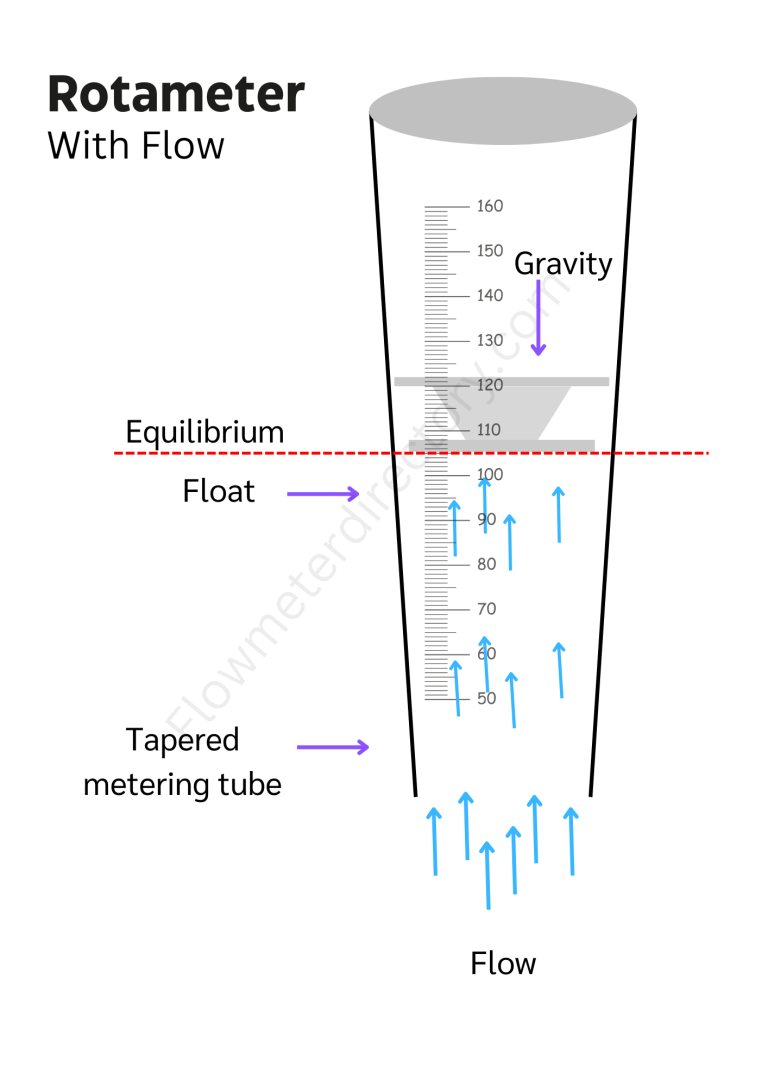

Someone might be wondering why rotameters are also called variable area flow meters. The explanation lies in the principle of variable area measurement, which is central to how these devices function. A rotameter consists of a tapered tube and a float inside. As the fluid (either a gas or liquid) flows upward through the tube, it pushes the float upward until an equilibrium is reached between the downward gravitational force on the float and the upward force from the fluid’s flow. Because the tube is tapered, the cross-sectional area of the tube increases as the float rises, allowing for a wider range of flow rates to be measured.

In essence, the variable area concept refers to the fact that as the flow rate increases, the float rises, and the area around it increases. This dynamic adjustment lets the rotameter accommodate a broad range of flow rates while providing a direct, visual indication of the current rate. Therefore, “variable area flow meter” is actually a generic term for this type of meter, often abbreviated as VA Meter (where V stands for “Variable” and A stands for “Area”).

However, the term “rotameter” became widely recognized, primarily because of Deutsche Rotawerke GmbH—a company initially specializing in these instruments. Founded in Germany, Rota popularized this flow meter design, leading to the device being referred to as a “rotameter” rather than the more generic “VA meter.” Today, Yokogawa Electric Corporation owns the Rota brand, which remains synonymous with high-quality variable area flow meters. The popularity of the term “rotameter” is a testament to Rota’s significant influence in standardizing and popularizing this technology across various industries.

Types of Rotameters

Rotameters come in several varieties, and each has unique properties. There are several types of rotameters, including flanged armored rotameters, low-cost sight and rate indicators, and glass tube flow meters.

Flange Armored Rotameters – The flange armored rotameters have several different connection sizes, including ASME, DIN, and JIS numerous threaded fittings and flange variants to offer for versatile installations, widely used as a mechanical indicator alternative that do not require power, which lowers installation costs and makes it an affordable option for measuring flow in potentially hazardous areas.

Glass Tube Flow Meter – A glass tube rotameter is a type of low-cost rotameter that is normally used in many general applications.

Why Use a Rotameter?

Rotameters are extremely popular in almost in every industry. They are easy to use, easy to understand and often easy to replace. Several manufacturers have taken a further step to produce rotameters in different styles and with different options.

Rotameters provide a direct visual indication of flow rate, making it easy for operators to monitor without specialized equipment. As the flow rate changes, the float moves up or down within the tapered tube, clearly marking the current rate.

Rotameters can be used for both liquid and gas flow measurement, making them suitable for water treatment, HVAC systems, pharmaceutical production, chemical processing, and laboratory applications.

Featured Company

EESIFLO TECHNOLOGIES INC.

Phone: + 1 318 614 3971

Address:

– 3928 Highway 80 Rayville Louisiana, 71269,

– 4600 FM-307 Midland TX 79706 United States

FEATURED PRODUCTS

Brooks Armored Rotameters (Variable Area)

Overview The Brooks line of rugged metal tube variable area meters (rotameters) is ideal for high pressure, high temperature, and other demanding flow applications where

Voegtlin Rotameter Flowmeter Q Flow

Overview Our proven Q-Flow is a modern VA-flowmeter (Rotameter) for gases built on the variable area principle. Designed in close collaboration with users, it combines

Voegtlin Rotameter Flowmeter V-100

Overview Vogtlin’s V-100 is a classical variable area flow meter (Rotameter) for gases and liquids with a broad line-up, great flexibility and extensive options. The

Rotameter yokogawa The RAMC Rotameter

Overview The short-stroke Rotameter RAMC allows the measurement of high flow rates using a relative short metering tube. It is a stainless-steel armoured construction for

Malema 6000 Series Glass Tube Rotameters

Overview Malema’s 6000 series glass tube rotameters are designed according to VDI/VDE 3513 standards. Series 6000 glass tube rotameters are designed according to VDI/VDE 3513

SERIES KM* : FLOW RATE INDICATOR

Overview Full scale flow ranges from 6 GPH to 220 GPM Connection size 1/4-inch to 3-inch NPT or BSP Features Full scale flow ranges from

SERIES FSR : LOW COST SIGHT AND RATE INDICATORS

Overview Full scale flow ranges from 5 to 100 GPM (20 to 380 LPM) and 10 SCFM to 250 SCFM Connection sizes from 1/4-inch to

SERIES FIS : LOW COST RATE INDICATORS WITH SWITCH

Overview Full scale flow ranges from 4 to 100 GPM (16 to 380 LPM) and 10 SCFM to 250 SCFM Connection sizes from 1/2-inch to