BS&W Monitors for LACT units & Crude Oil Pipelines

Even till now, the LACT unit operators have a name of their own for the water in oil monitor. It is common to hear folk referring to it as either a BS&W PROBE or BS&W MONITOR.

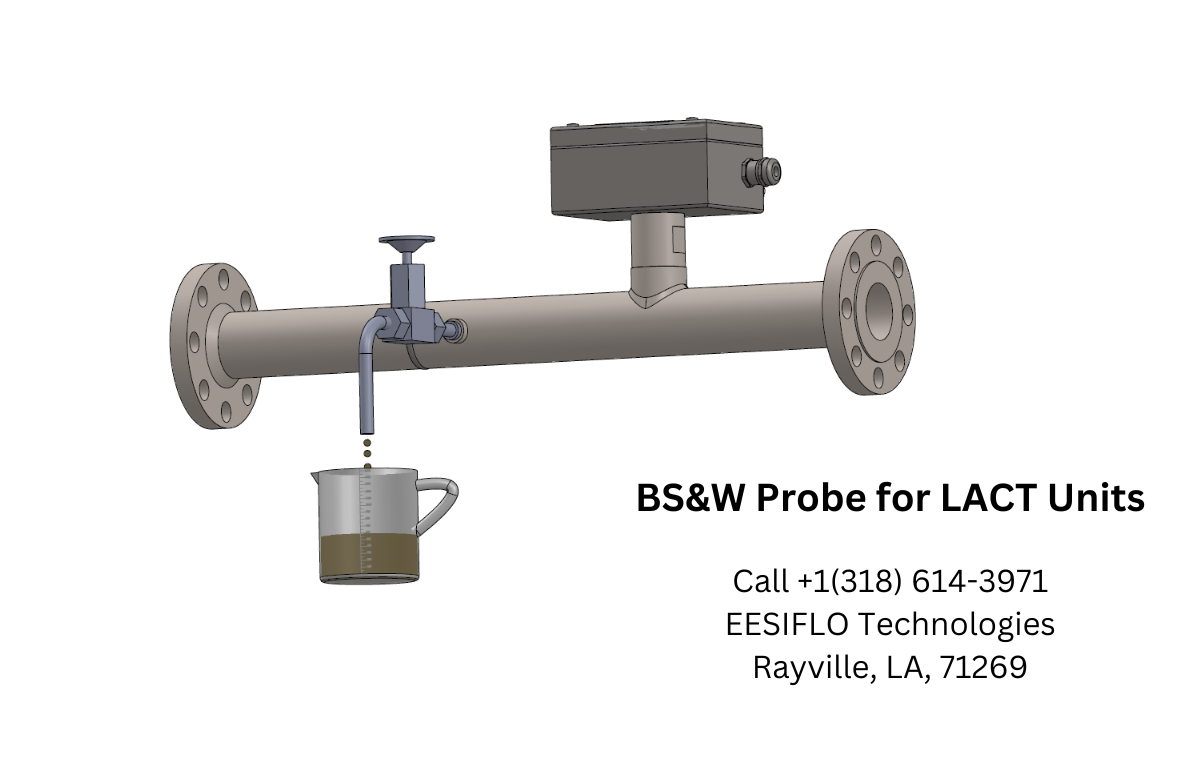

The monitor is commonly used to measure Basic Sediment and Water (BS&W) and a LACT unit will use a BS&W monitor along with an automatic sampler. In this case, a manual sampling valve can be added for crude oil spot samples.

Why Use a BS&W probe?

The main reason is that it is normally part of the specification although Coriolis meters have become more common.

Affordable solutions for larger pipes. Inline Oil Cut Measurements!

Call: +1 (318) 614-3971

or

3928 US-80, Rayville, LA 71269, United States

4600 FM-307 Midland, TX 79706

United States

Traditional LACT Unit BS&W Monitoring

The system consists of an inline “BS&W monitor” that monitors the flowing stream and communicates to an electronic display device which will know if the LACT Unit is experiencing an excess BS&W content which actually means that there is excess water in the pipeline which needs to be routed to a place where it can have the water removed before selling.

A high level trigger point is normally set for the BS&W probe/ monitor at around a small percentage of BS&W in oil e.g. 3%. When the BS&W controller reaches this point it will send a signal to have a 4 way diverter redirect the crude oil back to the treatment facility . The normal flow operation will be reset back to normal once the BS&W probe detects that water content has gone back to an acceptable level.

The EASZ-1 BS&W monitors are manufactured in all stainless 316S and generally installed in a vertical run of pipe for LACT applications. As the amount of BS&W changes for a particular gravity of crude oil, so does the dielectric constant. With the aid of the BS&W Monitor, a BS&W adjustment can be set that will provide an electric output when the percentage BS&W setting is exceeded.

Full-cut Monitors 0-100 Percent

EESIFLO Technologies Inc.

3928 Highway 80, Rayville Louisiana 71269

https://eesiflo.com/full-cut-meter/

These monitors differ from the traditional type of bs&w monitor because of their ability to measure oil cut as well as water cut. This means that the process operator can easily evaluate how oil wells are producing. Our full-cut oil meters use a wide range oscillating principle to enable high measurements of water percentage, even salt contaminated water.

Other Applications for the EASZ-1

- Emulsion Control

- Petroleum by-products

- Desalters

- LACT units

- Dewatering

- Oil Quality Control

- Oil Water separator Vessels

- Wash Tank Effectiveness

- Free Water Knock outs

- Heater Treaters

- Separation Vessels

- Hydrocarbons

Industries

- Oil Production

- Oil Distribution

- Refining

- Petrochemical

- Chemical Plants

- Pharmaceutical

- LACT Skid Manufacturing

About the producers of the EASZ watercut meters

EESIFLO is a company that first specialized in Water Cut Monitors ( which are also known as WFM, OWD, BS&W & Water in Oil Analysers) for the Oil & and Gas, Petrochemical and chemical industry. Many of our compact mini units are also referred to as moisture in oil sensors and our clients have installed them in lubrication systems in power plants as well marine applications. Our main facility in the USA is located in Rayville Louisiana with an annex in Texas.

All EESIFLO’s products are built in-house and the company has been successfully delivering it’s own EASZ water-oil transmitters and monitoring systems for more than 2 decades. EESIFLO’s history is a colorful one where or organisation was previously involved in crude oil and natural gas sampling solutions until we decided to focus more on inline, online and realtime measurement devices for crude oil (known as the EASZ-2) which uses a wide range oscillator instead of simple direct capacitance measurements. These techniques limit the effect of quasi signals and together with a much better resolution.

Capitalizing on the market knowledge of its founder Mr David Michael Hughes (a qualified chemical engineer from the UK) , the EASZ water in oil transmitters have been successfully installed in a wide range of industrial applications in almost every major industrial zone in the world. Apart from this, the company has also custom designed and built watercut meters using insertion probe designs and with built in static mixers. The EASZ watcher software is also available as answer to client requirements where multiple watercut meters are being monitored using RS485

We try not to compete with our clients.

Although we are familiar with LACT units and metering, we do not compete with our clients (many of them being manufacturers of metering skids) and have never had any aspirations to do so up till now. We supply to any skid fabricator who is looking for a high quality watercut meter with support. The foundation of the company and its success is the company’s vision to be a supplier of specialized measuring equipment with a focus on inline measuring devices.