|

| Water in Oil Measurement Methods – EESIFLO |

| The EASZ-1 Online water in oil meters WIO & WIF (water in fuel) meters manufactured by EESIFLO can be installed… |

Water in Oil Measurement Methods – EESIFLO |

|

|

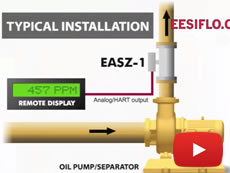

The EASZ-1 Online water in oil meters WIO & WIF (water in fuel) meters manufactured by EESIFLO can be installed in general industry applications to measure lubrication oil quality, hydraulic oil and fuel, water in fuel emulsions (WiFE) and water in oil emulsions. The units are excellent for measuring water contamination in diesel to protect marine diesel engines from water ingress. Also popular with LACT systems for base sediment and water determination, acting as a switch device for four way diverter valves. Also combined integrator project with FMC also known as “Fuel Management Computers” It is an online method for water in oil and fuel measurement such as diesel fuel and gasoline that is practical and economical and more often in combination with crude oil sampling systems. The oil analyzer is used for analysis of oils and fuels. The percentage measurement version is normally seen in crude oil applications. It can be used in conjunction with a bs&w centrifuge or karl fischer methods- titration for calibrating water cut percentage in low or high ranges. An additional bs&w formula calculation of total oil/water is achieved by a proportional to flow signal to a net oil computer. Free water percentage in the oil is then known by volume over time. The water cut analyzer is the same device as the BS&W meter also known as a bs&w probe or bs&w analyser except that they are implemented in slightly different applications. What is commonly known as a bs&w probe is actually a water in oil monitor with used in a hazloc environment. The same technology is also beneficial to lubrication and fuel systems, especially on the outlet of separators in a similar way to water cut analyzers installed in the outlet of oil and gas two and three phase separation units. |