Despite the introduction of innovative technologies that measure flow using various principles, the electromagnetic flow meter—or magmeter—continues to hold a strong position as a preferred solution in many industries. Its enduring popularity can largely be attributed to its reliability and the confidence it inspires among consultant engineers and industry professionals. Many engineers who specify flow meters in projects are deeply familiar with electromagnetic technology and trust it to deliver accurate and consistent performance across a wide range of applications. This trust has been built over decades of use in challenging environments, such as water treatment plants, chemical processing facilities, and wastewater management, where magmeters have consistently proven their durability and precision.

For more information on our range of Magmeters available in the USA visit: https://meterdata.com/

How Magnetic Flow Meters Work

Magnetic flow meters, also known as magmeters, operate on Faraday’s Law of Electromagnetic Induction, which states that a voltage is generated when a conductor moves through a magnetic field. In the case of magnetic flow meters, the fluid acts as the conductor. When the fluid flows through the magnetic field created by the electrodes inside the flow meter, it generates a voltage that is directly proportional to the fluid’s velocity.

Magnetic Field Creation: Two electrodes are placed on opposite sides of a non-magnetic flow tube, while copper coils within the meter generate a magnetic flux across the tube.

Fluid as the Conductor: As the conductive liquid (like water or slurry) flows through this magnetic field, it creates a voltage that varies with the flow rate. The faster the fluid flows, the higher the voltage produced.

Voltage Measurement: The electrodes pick up this voltage, which is then measured by the flow meter’s electronics. Since the voltage is directly proportional to the flow rate, the device can calculate and display the fluid’s velocity and flow rate.

To help demystify the inner workings of magnetic flow meters, we have produced an animation that illustrates how the magnetic flux is generated by copper coils and shows how flow velocity is determined by measuring the voltage across the electrodes.

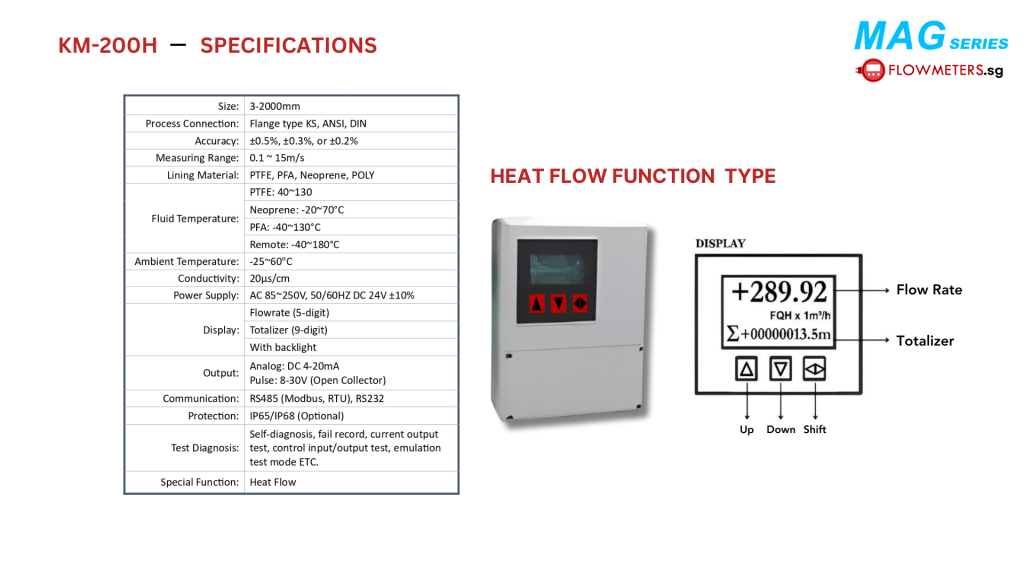

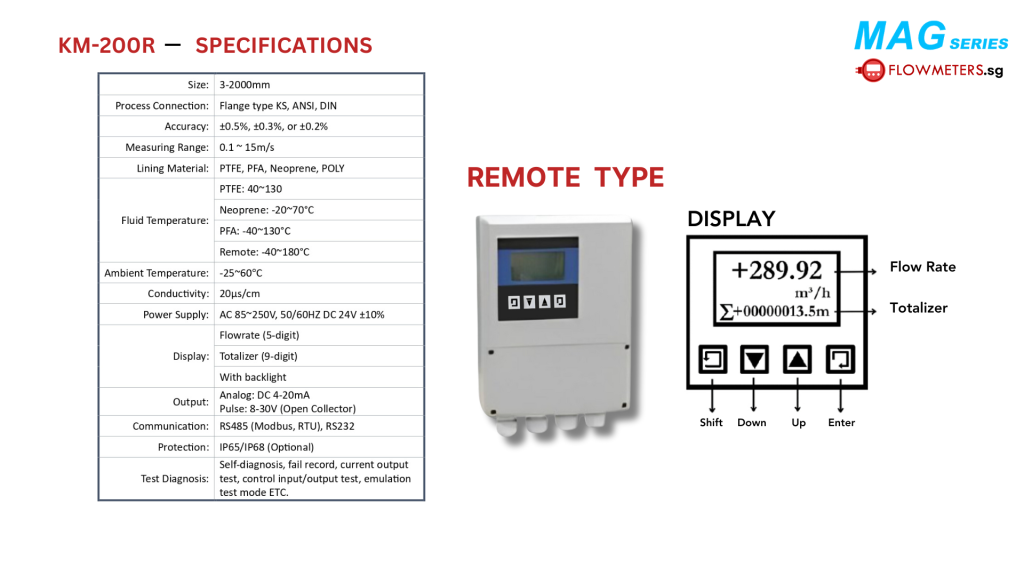

MAG Series is a high-quality Magnetic Flow Meter that measures volumetric flow rates of conductive liquids. This will include drinking water, industrial water, wastewater, sewage and cement slurry.

Magnetic flowmeters can also be offered with sanitary connections for food applications such as milk and dairy products. The output flow signal is directly proportional to the flow velocity.

We provide the magnetic flow meter and a calibration certificate from International Laboratory Accreditation Cooperation (ILAC), a certified calibration house. The MAG Series housing and internal electronics are all sealed and welded to ensure the protection of electronics and the operator.

MAG Series Flow Meter

Magmeter Applications

- Water abstraction flow

- Water purification and desalination flow

- Drinking water distribution networks

- Revenue metering or billing

- Leakage detection

- Irrigation flow

- Industry water

- Cooling water flow rate

- Wastewater flow

- Sewage and sludge flow

- Sea water flow

Magnetic Flow Meter Advantages

- Obstructionless design

- Linear output

- Corrosion resistant wetted parts

- High accuracy

Typical Magnetic Flow Meter Applications