|

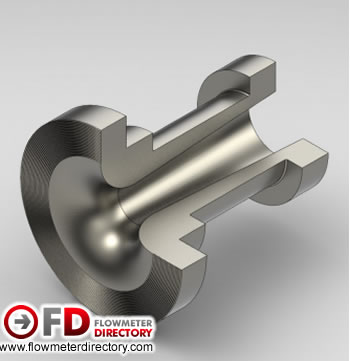

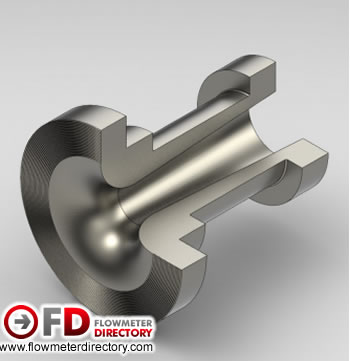

CPA Sonic Nozzles Overview

Our Protection Class Nozzles can be manufactured to protect all types of positive displacement, turbine and orifice meters. They may also be ordered with pressure taps which allow our nozzles to perform backup or secondary gas measurement service; acting as a redundant device in the subsonic regime and as an overspeed protection device when choked.

Our Calibration Class Nozzles are manufactured to exacting standards in a material of your choice. Once machined and inspected, the nozzles are calibrated at one or more recognized, independent labs, according to your specifications. Our calibration class nozzles provide unparalleled repeatability and flat-line choked flow performance.

CPA Sonic Nozzles Features

- Zero maintenance, low fouling rate and a simple concept

- Accuracy to suit need (0.1% – 1% of mass flow reading)

- Good pressure recovery (less than 15% drop)

- Reliable protection for reference meters, regardless of pressure or temperature changes

- No costly meter failures due to fluid overspeed scenarios

- Eliminates expensive redundant measuring devices

- Comparison to secondary measurement signals any problem that may arise with the primary meter

- Manufactured for all meter type and available in a range of sizes: NPS 1/2 to NPS 24

- Eliminates the hazard of H2S venting by control valve systems in sour gas applications

- Nozzles are manufactured to recognized industry standards, such as ASME/ANSI, or with a stepped throat which increases stability at critical conditions

- Industry Round Robin data is available providing confidence levels associated with your choice of calibration facilities

|