How do Thermal Mass Flow Sensors work?

This is a basic explanation on some of the most common types of Thermal Mass sensors. There are of course, other variations which may add a twist to the concept and the measurement. These devices are popular for measuring air and gas flow, but some manufacturers have designed the sensors to also work with liquids.

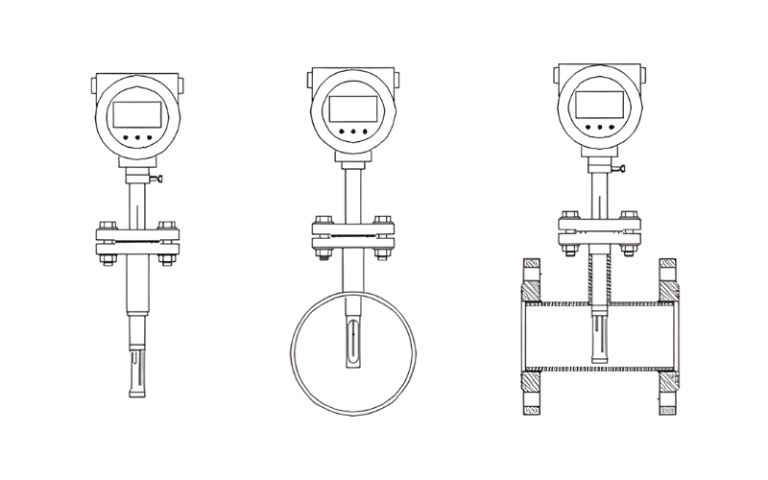

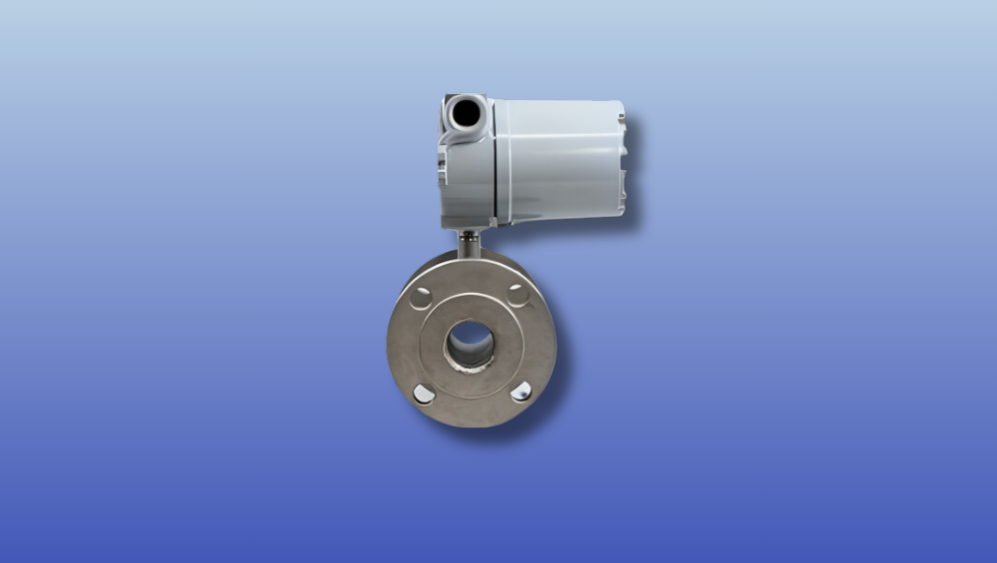

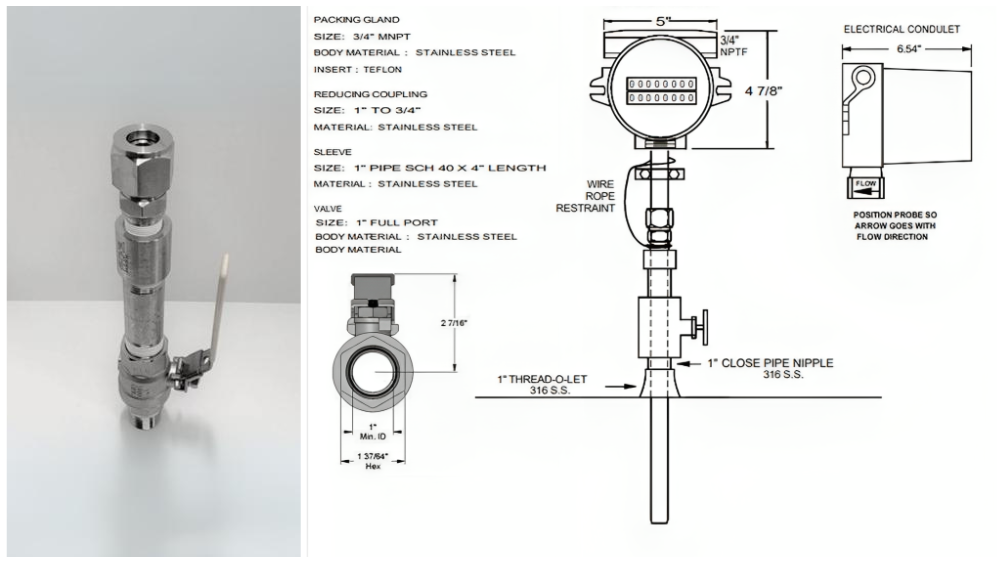

Thermal probes are versatile instruments that can be conveniently installed in existing pipework at the site location, often using screwed or flanged connections. These connections allow for easy integration into pipes and ducts to accurately measure the temperature differential (ΔT) of a flowing medium, which is essential in various industrial applications.

Engineers and Technicians recognize this as a measurement of a differential. In this case it is the difference between the actual temperature being measured (by a PT 100) and the constant temperature of the heated sensor.

This ΔT measurement is fundamental for accurate flow and energy calculations, as it provides real-time data on how much the medium has heated or cooled, based on the difference from the reference temperature. Such information is invaluable in monitoring thermal energy flow in HVAC systems, heat exchangers, and industrial processes, where maintaining specific temperature ranges is critical to system performance and efficiency.

To understand how an insert probe works, it’s helpful to visualize its internal components. Inside the probe, there are two distinct sensors: one that is heated and another that remains unheated. Although these sensors are often encapsulated together, giving the appearance of a single rod, it’s crucial to recognize that there are always two separate sensors. The heated sensor is designed to maintain a constant temperature, serving as a reference point, while the unheated sensor actively measures the actual temperature of the medium within the pipe or conduit.

This two-sensor design enables the probe to calculate the temperature differential (ΔT) between the heated and unheated sensors, providing valuable insights into flow conditions. The heated sensor’s stability allows it to determine how much heat is lost to the flowing medium, which helps gauge flow speed and turbulence. By combining the data from both sensors, operators can achieve precise assessments of flow dynamics, essential for maintaining efficiency and control in applications such as HVAC systems, industrial flow control, and environmental monitoring.

When the flow increases, the heated sensor will begin to cool. In order for the heated sensor to maintain it’s steady temperature, more energy will be needed to heat it up. The amount of energy required for the heated sensor to maintain it’s constant temperature is directly proportional to the flow velocity e.g. feet per second or meters per second.

In a pipe or a conduit, flow velocity can be used to calculate the volumetric flow if the diameter of the pipe/conduit is known. An over simplified calculation (without corrections for Reynolds numbers) can be understood by spending time with a flow velocity to volume calculation e.g.

Pipe Flow Calculator

What else?

Full Bore Flow Through Types

Natural Gas Flow Switch

Applications

- Compressed air flow monitoring

- Boilers – natural gas power

- Monitoring Hydrogen flow

- Gas Mixers – additive injection

- Testing for leaks in valves

- Kiln applications

- Purge Gas and Air

- Biogas Monitoring

- Test Separator Gas Outlet leg

- Oxygen Flows

- Air Dryers – flow rate

- Flare gas stack velocity monitoring

- Flow rate of nitrogen blanketing for tanks

- Propane pipeline flow

- Argon Applications

- N2 nitrogen flow rates

- Aluminum smelter chlorine flow

- Compressed air

- Power Plants Gas and Air flows

- Combustion process air flow

- Genset gas flow rate

- Coal mining heated air flow

- Contaminant unit vent air flow

- Digester gas projects requiring gas flow

- Carbon-Dioxide in beer manufacturing

- Air vent systems

- Compressor air flow

- Natural gas consumption

- Powder plant air flow

- Paint booth/paint oven ventilation

- Engine test stands air flow measurement

- Fuel cell hydrogen flow

- Natural Gas Transmission

- Natural gas to compressor stations

- Natural gas to gas-fired compressors

- Landfill gas GHG emissions reporting and Dump Gas

Applications

- Air

- Ammonia

- Biogas

- Butane

- Hexane

- Chlorine

- Compressed air

- Carbon monoxide

- Carbon dioxide

- Digester gas

- Dump gas

- Ethane

- Helium

- Hydrogen

- Methane

- Natural gas

- Nitrogen

- Oxygen

- Propane

Made in USA

Insertion Type – We can configure a flow meter to fit into an existing pipeline.

Affordable solutions for larger pipes. Measure gas with ease!

Call: +1 (318) 614-3971

Address: 4600 FM-307 Midland, TX 79706 United States

Website: meterdata.com

Our facilities are located in Rayville Louisiana where we provide liquid and gas flow solutions for our customers in the US.

We make it easier because you can purchase or rent a flow meter.

For our other liquid flow meter solutions visit this website:

Featured Company

EESIFLO TECHNOLOGIES INC.

Phone: + 1 318 614 3971

Address:

– 3928 Highway 80 Rayville Louisiana, 71269,

– 4600 FM-307 Midland TX 79706 United States